|

+86-393-8910238 |

|

+86-393-8910236 |

|

info@hydrocarbonresins.com |

|

hydrocarbonresin@hotmail.com |

| 8618239338158 |

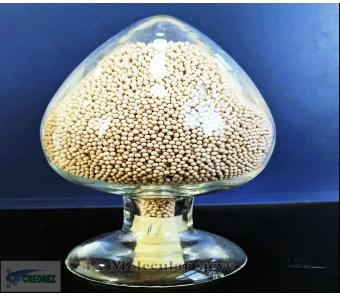

4A Molecular Sieve |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PDF: Not | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Introduction to 4A Molecular Sieve:

4A molecular sieve is a kind of potassium-sodium aluminosilicate with LTA-type skeleton structure which is composed of silicon-oxygen and aluminum-oxygen tetrahedrons.The main crystal hole of the 4A molecular sieve is an eight-membered ring structure, and the crystal pore size is 4Å (0.4nm).It can adsorb water, methanol, ethanol, hydrogen sulfide, sulfur dioxide, carbon dioxide, ethylene and propylene, but does not adsorb any molecule with diameter greater than 4A (including propane). Its selective adsorption performance for water is higher than that of any other molecule.It is one of the largest molecular sieves varieties in industry.It is widely used in the drying of gases and liquids, and also in the refining and purification of some gases or liquids, such as the preparation of argon.

Specifications:

Regeneration:

Moisture removal: The Products can be reactivated by thermal sewing. The temperature of the inlet gas through the molecular sieve bed should be 200-350℃ and the pressure 0.3-0.5kg/cm2 while The temperature of the outlet gas from the bed should be kept at 150-180℃

Organic gas removal: First the vapour is used to remove the organic substance, then the moisture is displaced.

Recommended Application:

1) Drying and removing of CO2 from natural gas, LPG, air, inert and atmospheric gases, etc. 2) Removal of hydrocarbons, ammonia and methanol from gas streams (ammonia syn gas treating)

Package:

Net 150KG/160KG galvanized metal drum.

Net 25KG carton box lined with aluminum foilg bag. Net 140KG/160KG fiber drum.

Net 1000KG container bag or other packings.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CHINESE

CHINESE ENGLISH

ENGLISH